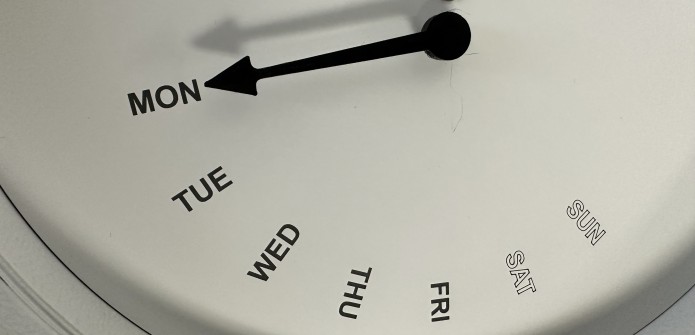

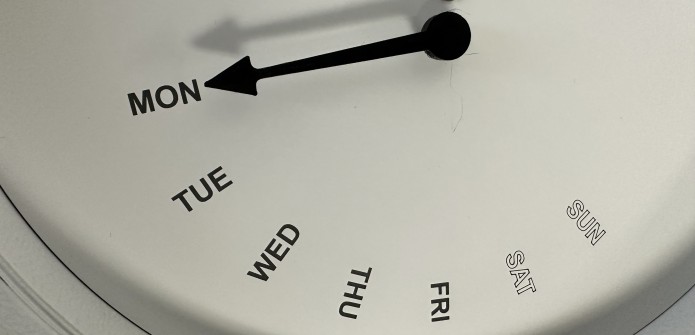

Inspired by high-end wristwatches with retrograde hands, I decided t create a wall-mount version of an analog representation of the day and week for my office. I like to see the current date relative to the month’s or week’s end.

Continue reading

Inspired by high-end wristwatches with retrograde hands, I decided t create a wall-mount version of an analog representation of the day and week for my office. I like to see the current date relative to the month’s or week’s end.

Continue reading

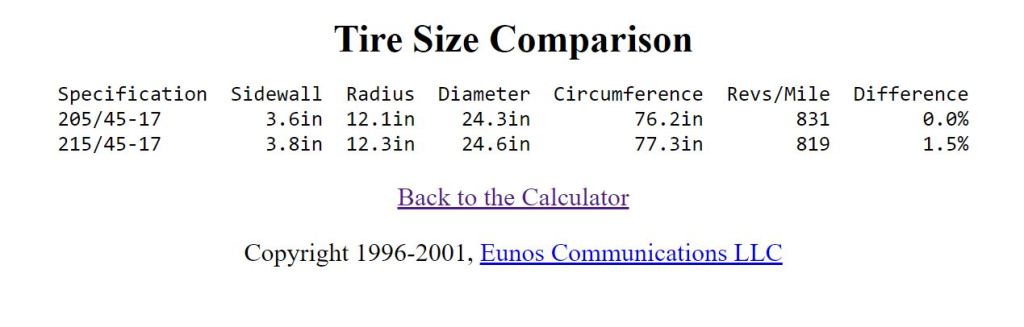

I recently decided to change the tires on my car to Michelin 215/45ZR-17 MICHELIN PILOT SPORT 4S because the original size 205 was not in stock anywhere. After more research, I think size 215 will look better. However, the downside of this is that the diameter of that tire is 0.3″ bigger, which will cause incorrect odometer counting. Here is the calculation using the Miata.net calculator:

This means that the speedometer will show 60mph, while the actual speed is 60.9mph and the odometer will show a lower value over time (150miles less for every 10,000). It is not a big deal, but for sake of accuracy, I decided to correct this with one of my devices. In the Mazda MX-5, the Instrument Cluster gets information about speed via CAN bus, from message ID 0x202. I used these messages for my digital speedometer implementation. So, to correct the speed information all we need is to intercept this CAN message and recalculate in real-time, according to the Tire Size Calculator. My RF roof controller is basically doing the same thing with speed info, to override the default speed limit of 6mph. I can reuse the same hardware design for correcting speed in the Instrument Cluster. All that’s needed is a new plug-n-play harness attached between the Instrument Cluster and the main harness. I think this device will be useful for people who want to/or have changed wheels size or any non-OEM size tires.

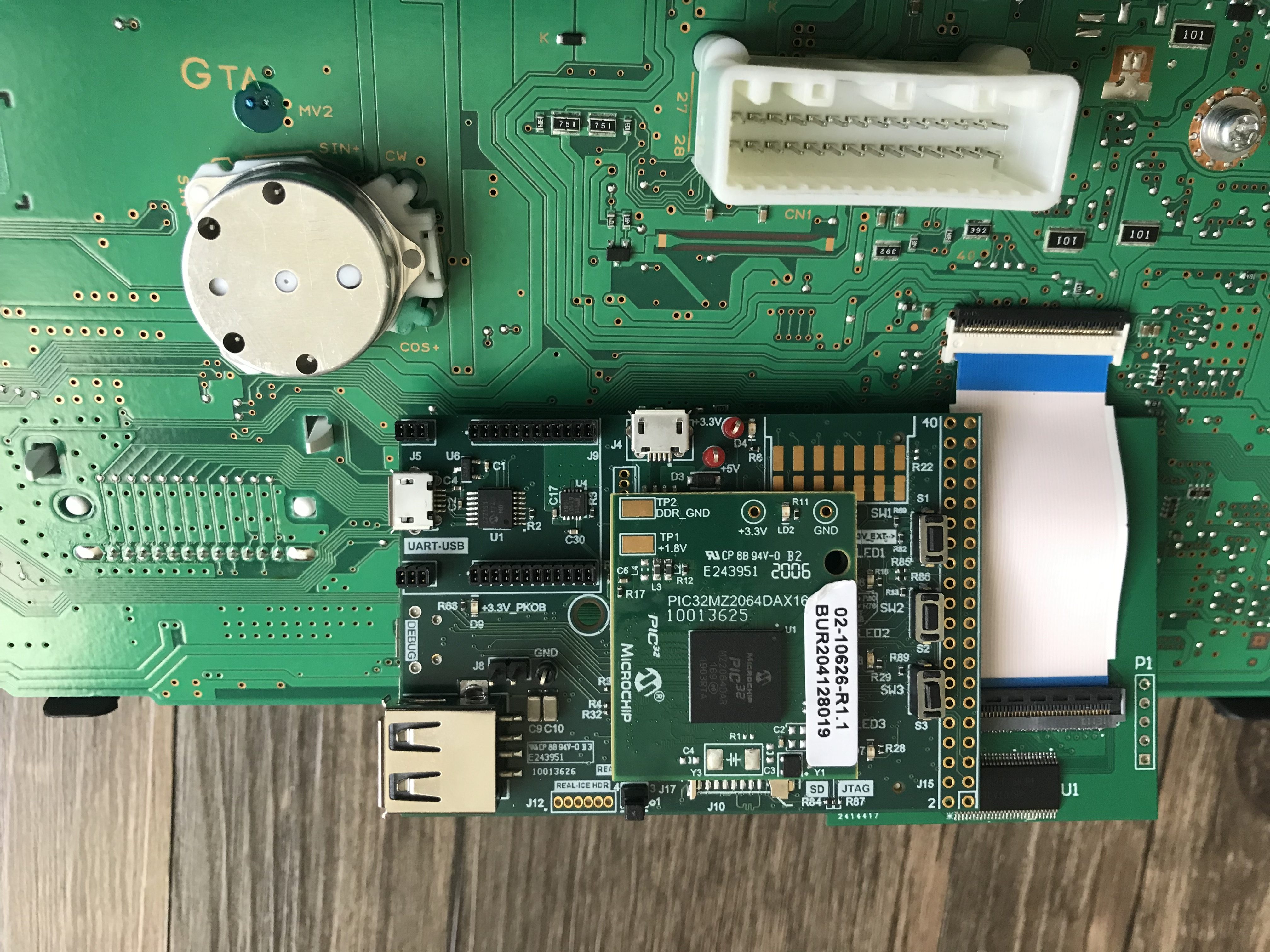

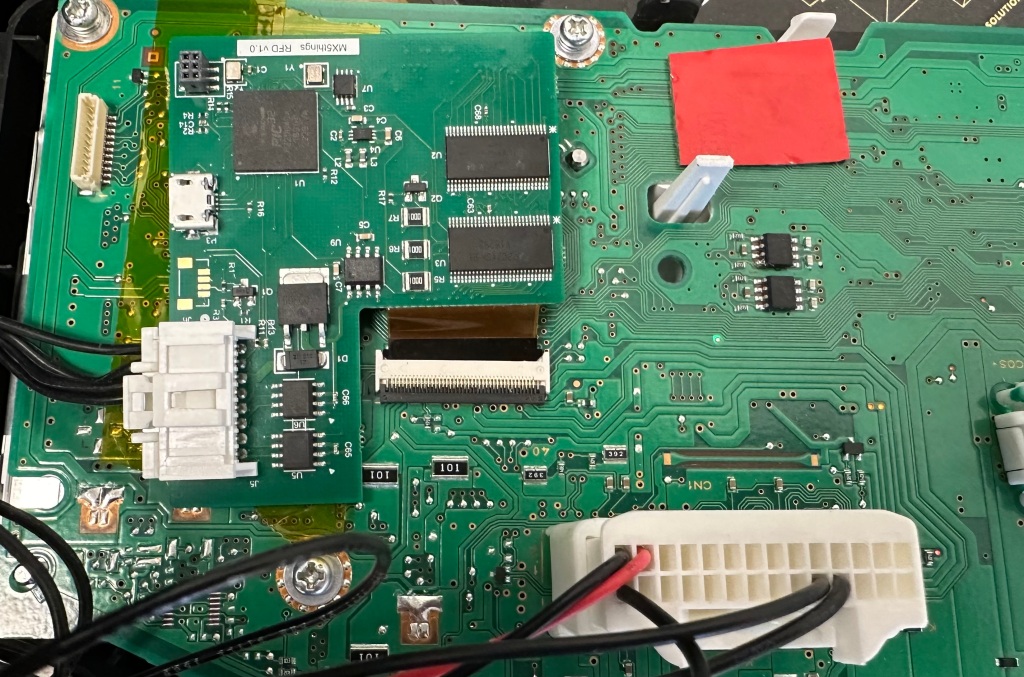

The Mazda MX-5 RF has a graphic LCD screen as part of the Instrument Cluster. I thought it would be cool to access it to show additional information on that screen. The LCD is 4.6″ with an FPC cable to the mainboard. The LCD is controlled by the graphic processor Yamaha YGV642, which would be the perfect option for customization. Unfortunately, Yamaha denied my request to share the datasheet and I could not find anything in the public domain. I decided to use an external graphics processor and implemented a video switch, to control the LCD. To accelerate development, I chose the Microchip development board and made a simple PCB with connectors and a video switch.

Of course, it is bulky, but I got immediate access to the LCD screen and can start work on software. The LCD screen has a resolution of 432×432 pixels with a simple RGB interface, 6 bits per color, with a 62 Hz frame rate. I was able to synchronize my processor with Yamaha, which allows me to insert a portion of my graphics and leave some untouched. My first test was the implementation of a digital counter.

The first project is the implementation of the digital speedometer. Current speed is available on the CAN bus, so it makes it easy to capture it using just one wire soldered to the mainboard, directly to the Rx output of the CAN receiver chip. Switching from “mph” and “km/h” is also available through CAN messages. I implemented this as well. The speedometer comes on screen after four clicks on the “Info” button, and the next click will turn it off. During the road test, I found that the digits switched too quickly when the speed was on the borderline of the next number. To avoid this I implemented a simple filter, averaging 32 samples. Now it is perfect.

The next project will be an implementation of an analog clock, which will show up when the engine is turned off and stay until you open the door or click the Info button to another feature.

The power reserve handle will show the battery’s voltage, which will be useful to see when the engine is off.

I will design a smaller single PCB with a microprocessor and FPC connectors to make installation simple. CAN bus is not present on the FPC connector, so one wire needs to be directly soldered to the mainboard. The software can be updated at any time via a USB cable.

Update 11/29/2023

Finally some progress with this project.

PCB with flex cable assembled. Added analog interface to connect external temperature sensor.

You can put the roof down while you approaching the car, how cool is this?

After successful implementation of the one-touch roof control module, next idea is to do this using a key fob from outside the car.

This is a very challenging task because the roof mechanism operates only when Ignition power is on. To solve this problem, I modified my ACC controller to control the IG relay instead. This module would listen to CAN messages and when activate IG relay when needed by pressing Lock or Unlock buttons on the key fob. After roof operation completed (which is also known as an event on the CAN bus) IG relay will be turned off. RF controller also can listen to CAN bus for key fob messages and activate mechanism when needed.

Quick implementation was successful, and I got everything working as desired. Because I already had Windows Controller installed, everything is fully functional. Technically windows controller could be optional, but if you leave windows down and then remotely put the roof up, there is no way to close windows without entering the car again. Also, in a US car after closing the roof, windows will leave a gap of 1″, which I can close remotely with one more click.

We tested it with RF 2017 and RF 2020, MT and AT versions.

This product will be available by end of June 2021 from our store.

One of the most popular modifications for MX-5 RF is adding the “SmartTop” module made by mods4cars. This is a very simple electronic device, but it cost over $300, I think because there is no competition. I decided to design and produce my own version of such a device. Basically, it is just a CAN bus bridge, which can filter can messages, to trick the roof mechanism by blocking messages which will disable operation (like higher speed, car in reverse, etc). My previous project for the front camera kit has a similar design, so it was easy to reuse it for this project.

Implementing a one-touch feature is very simple as well, because the roof control switch produces only two voltage levels, to keep the roof opening or closing.

Another idea for this device is to be able to control the roof using the key fob like it is done in BMW Z4 for example. So you open the roof while approaching the car. This is quite a challenging task because the roof mechanism operates only when Ignition power is on and other modules on the CAN bus operational. I’m hoping to override these limitations by integrating the IG power switch for the roof controller in my device and substitute the CAN messages for initial communication.

My first version of this device now operational for all basic features. The software can be updated at any time via USB cable. To do this, my son made for me a Windows application.

Because I have to have communication with Key Fob, I found that it would be useful to have different configurations assigned for each key fob. If you need to give the car to someone else, you can share a key that has disabled the new feature, to avoid confusion at the service center for example. Or for valet parking, you can share the key with completely disabled roof control, so they can’t play with this feature.

Hardware installation will be exactly the same as for “SmartTop”, YouTube has tons of videos on how to do this.

The module it self 50mm x 59mm x 18mm. It has a Micro USB connector for programming, LED status and a 16 pin connector for the main harness, similar to “SmartTop” is using. This device with a harness will be available in my store for $159.

You must be logged in to post a comment.